back to CATEGORIES

Polyurethane Powder Coating

Polyurethane Powder Coating

The series of products are mainly based on saturated hydroxyl polyester resin and isocyanate curing agent. They are thermosetting polyurethane powder coatings with superior weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance.

The series of products are mainly based on saturated hydroxyl polyester resin and isocyanate curing agent. They are thermosetting polyurethane powder coatings with superior weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance.

Powder Properties

Powder Properties

· Specific gravity: 1.2~1.8 g/cm³

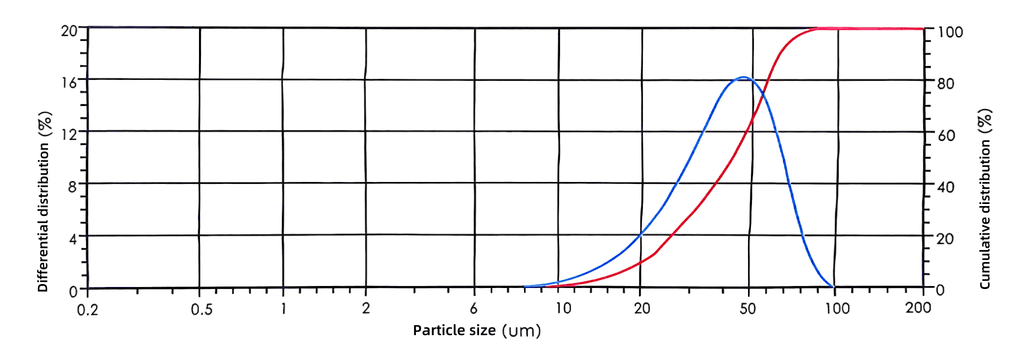

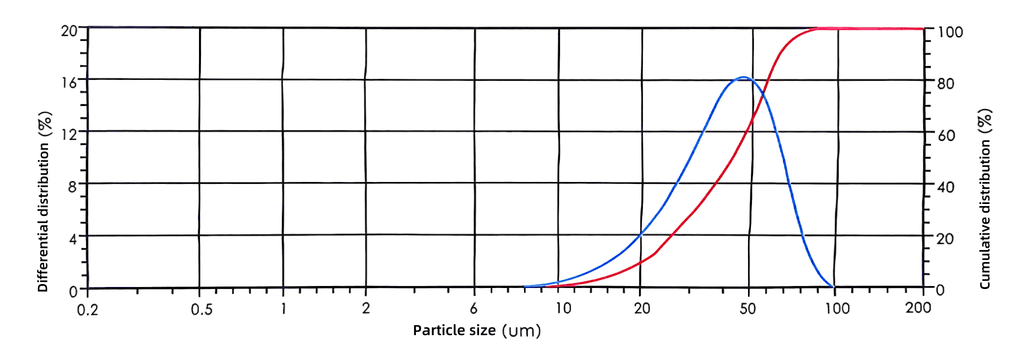

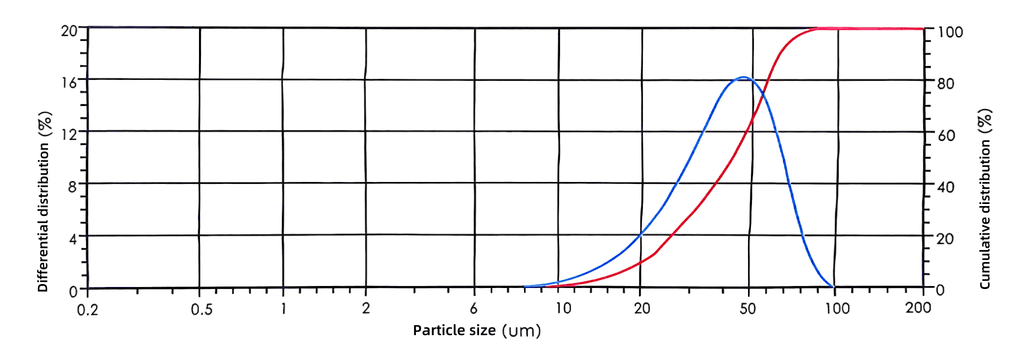

· Particle size: average particle diameter generally 30~38 µm, with >99% of particles <66 µm. Please specify any special requirements in advance.

· Flowability: Exhibits good fluidization and transport properties; fluidization index available upon request from the company.

· Storage stability: Can be stored at <25°C for up to one year.

· Specific gravity: 1.2~1.8 g/cm³

· Particle size: average particle diameter generally 30~38 µm, with >99% of particles <66 µm. Please specify any special requirements in advance.

· Flowability: Exhibits good fluidization and transport properties; fluidization index available upon request from the company.

· Storage stability: Can be stored at <25°C for up to one year.

Coating Performance

Coating Performance

Coating Performance

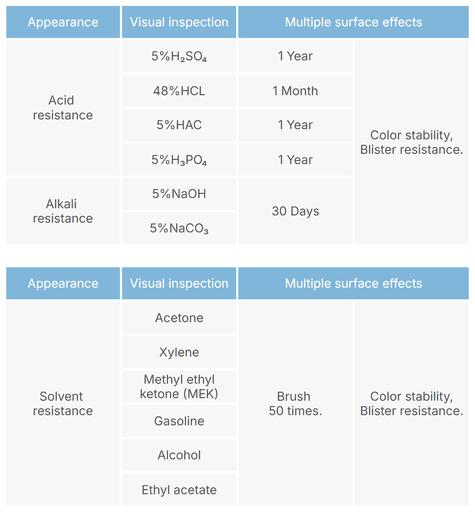

Appearance

Visual inspection

Multiple surface effects

Acid

resistance

5%H₂SO₄

1 Year

Color stability, Blister resistance.

48%HCL

1 Month

5%HAC

1 Year

5%H₃PO₄

1 Year

Alkali

resistance

5%NaOH

30 Days

5%NaCO₃

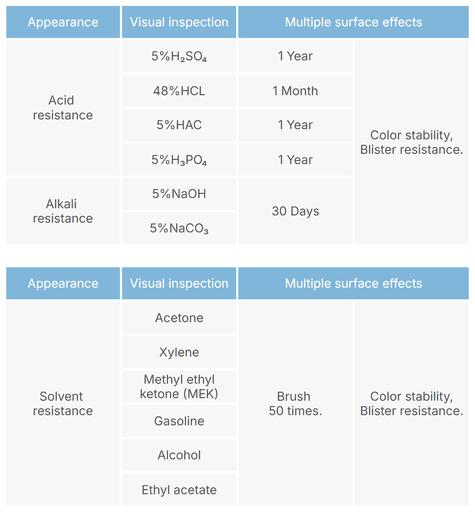

Appearance

Visual inspection

Multiple surface effects

Solvent

resistance

Acetone

Brush

50 times.

Color stability, Blister resistance.

Xylene

Methyl ethyl ketone (MEK)

Gasoline

Alcohol

Ethyl acetate

Particle Size Distribution Graph

Particle Size Distribution Graph

Particle Size Distribution Graph

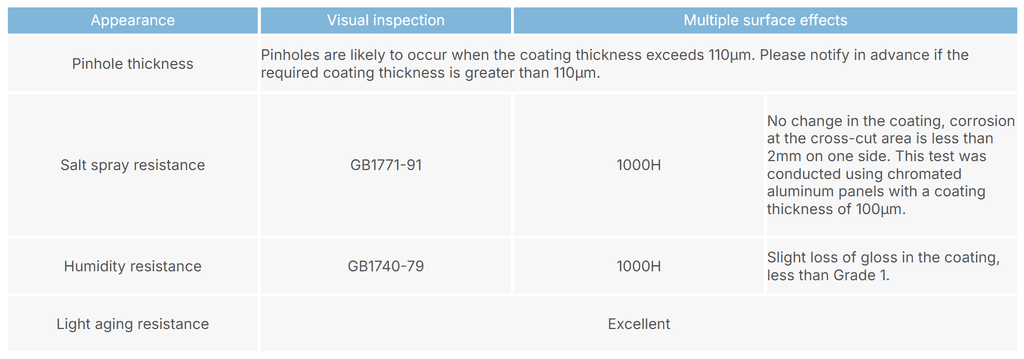

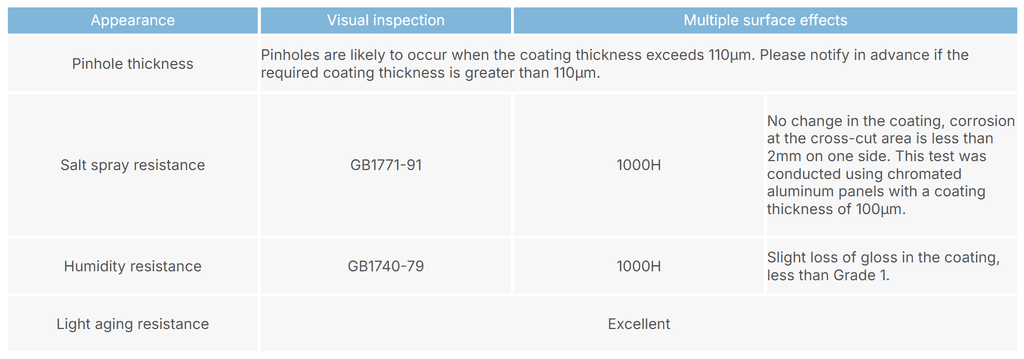

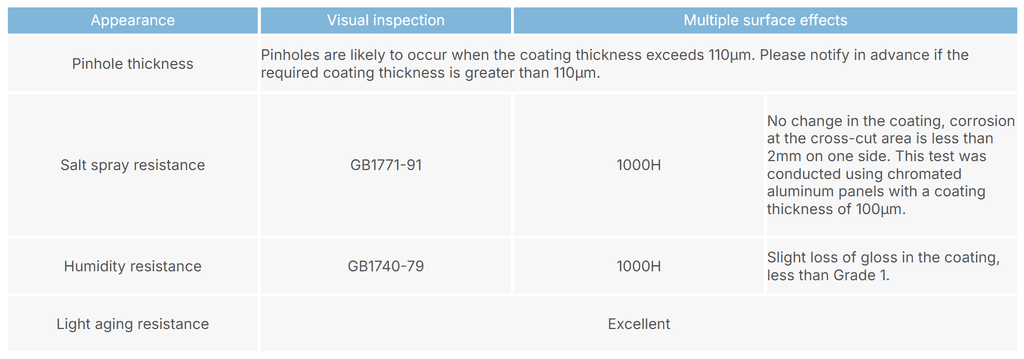

Appearance

Visual inspection

Multiple surface effects

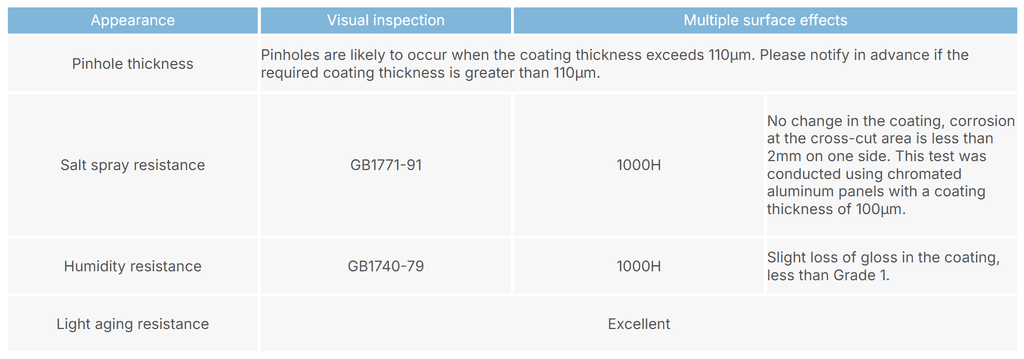

Pinhole thickness

Pinholes are likely to occur when the coating thickness exceeds 110μm. Please notify in advance if the required coating thickness is greater than 110μm.

Salt spray resistance

GB1771-91

1000H

No change in the coating, corrosion at the cross-cut area is less than 2mm on one side. This test was conducted using chromated aluminum panels with a coating thickness of 100μm.

Humidity resistance

GB1740-79

1000H

Slight loss of gloss in the coating, less than Grade 1.

Light aging resistance

Excellent

Application Conditions

Application Conditions

● Pre-treatment

Steel Phosphating

Note: Pre-treatment inspection should be conducted every 4 hours. The inspection method should follow the requirements of the chemical supplier or the company's pre-treatment instructions.

Steel Phosphating

Note: Pre-treatment inspection should be conducted every 4 hours. The inspection method should follow the requirements of the chemical supplier or the company's pre-treatment instructions.

Steel Phosphating

Note: Pre-treatment inspection should be conducted every 4 hours. The inspection method should follow the requirements of the chemical supplier or the company's pre-treatment instructions.

● Coating Application

This product series is suitable for the following application methods:

This product series is suitable for the following application methods:

· Corona electrostatic spray

· Tribo electrostatic spray

· Electrostatic fluidized bed coating (upon request)

· Fluidized bed dip coating (upon request)

· Other coating methods (upon request)

· Corona electrostatic spray

· Tribo electrostatic spray

· Electrostatic fluidized bed coating (upon request)

· Fluidized bed dip coating (upon request)

· Other coating methods (upon request)

Note: Coating quality inspection should be performed at least every two hours. The inspection method should follow customer requirements and the company's film inspection procedures.

Note: Coating quality inspection should be performed at least every two hours. The inspection method should follow customer requirements and the company's film inspection procedures.

● Curing Conditions

Recommended curing conditions: 200°C / 10 minutes.

Alternative curing conditions can be designed based on customer needs: 180°C / 15 minutes.

Recommended curing conditions: 200°C / 10 minutes.

Alternative curing conditions can be designed based on customer needs: 180°C / 15 minutes.

Recommended curing conditions: 200°C / 10 minutes.

Alternative curing conditions can be designed based on customer needs: 180°C / 15 minutes.

This product series is suitable for the following curing methods:

This product series is suitable for the following curing methods:

This product series is suitable for the following curing methods:

· Electric heating

· Radiation heating

· Infrared heating

· Oil or gas-fired heating (prior consultation recommended)

· Electric heating

· Radiation heating

· Infrared heating

· Oil or gas-fired heating (prior consultation recommended)

· Electric heating

· Radiation heating

· Infrared heating

· Oil or gas-fired heating (prior consultation recommended)

Note: Oven temperature should be checked regularly, with inspections conducted weekly.

Note: Oven temperature should be checked regularly, with inspections conducted weekly.

Note: Oven temperature should be checked regularly, with inspections conducted weekly.

Additional

Additional

● Application Areas

Air conditioners, outdoor furniture, highway guardrails and protective nets, outdoor power distribution cabinets, and other environments requiring ultra-high weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance.

Air conditioners, outdoor furniture, highway guardrails and protective nets, outdoor power distribution cabinets, and other environments requiring ultra-high weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance.

Air conditioners, outdoor furniture, highway guardrails and protective nets, outdoor power distribution cabinets, and other environments requiring ultra-high weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance.

● Special effects

Suitable for environments requiring ultra-high weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance. Various wrinkle, metallic, pearlescent effects, and mixed color finishes are available. For the use of special surface effect coatings, please refer to our company's usage guidelines.

Suitable for environments requiring ultra-high weather resistance, high corrosion resistance, high chemical solvent resistance, and high scratch resistance. Various wrinkle, metallic, pearlescent effects, and mixed color finishes are available. For the use of special surface effect coatings, please refer to our company's usage guidelines.

● Packaging and transportation

25kg cardboard boxes with polyethylene plastic bag liners. Non-hazardous goods, can be transported by various methods, but should avoid direct sunlight, moisture, heat, and contact with chemical substances.

25kg cardboard boxes with polyethylene plastic bag liners. Non-hazardous goods, can be transported by various methods, but should avoid direct sunlight, moisture, heat, and contact with chemical substances.

25kg cardboard boxes with polyethylene plastic bag liners. Non-hazardous goods, can be transported by various methods, but should avoid direct sunlight, moisture, heat, and contact with chemical substances.

● Health and safety

Please refer to our company's safety, health, and environmental operation guidelines, and request our "Safety Technical Report". For coatings intended for toys or food-grade applications, please specify in advance. Formulations will be carefully designed to ensure the absence of toxic elements and to avoid harm to human health.

Please refer to our company's safety, health, and environmental operation guidelines, and request our "Safety Technical Report". For coatings intended for toys or food-grade applications, please specify in advance. Formulations will be carefully designed to ensure the absence of toxic elements and to avoid harm to human health.

Please refer to our company's safety, health, and environmental operation guidelines, and request our "Safety Technical Report". For coatings intended for toys or food-grade applications, please specify in advance. Formulations will be carefully designed to ensure the absence of toxic elements and to avoid harm to human health.

MENU

Time of Business

Monday to Friday

9:30 - 18:30

CONTACT

alliedpowdercoatings@gmail.com

No. 1, Jinchen Road, Xiaoji Industrial Park, Jiangdu District, Yangzhou City, Jiangsu Province, China

© 2024 Allied Powdercoatings. All rights reserved.

MENU

Time of Business

Monday to Friday

9:30 - 18:30

CONTACT

alliedpowdercoatings@gmail.com

No. 1, Jinchen Road, Xiaoji Industrial Park, Jiangdu District, Yangzhou City, Jiangsu Province, China

© 2024 Allied Powdercoatings. All rights reserved.